Fatra FF807 Membranes

The Fatra fully adhered system uses our FF807 fleece-backed membranes in conjunction with the appropriate adhesives and primers to bond each layer of the build-up to the adjacent layer. This system can be used in a warm or cold roof application and over a range of substrates including concrete, plywood or profiled metal decking.

There are 2 standard roll sizes available:

|

Fatra FF807 Membranes

|

|

Reference

|

Fatra FF807

|

Fatra FF807V

|

|

Roll width

|

1,300mm

|

1,650mm

|

|

Roll length

|

15.4m

|

16.0m

|

|

Membrane thickness

|

1.5mm

|

1.5mm

|

|

Fleece weight

|

300g/m2

|

180g/m2

|

|

Total thickness

|

2.6mm

|

2.0mm

|

|

Area

|

20m2

|

26.4m2

|

|

Roll weight

|

48kg

|

54kg

|

|

Unit weight

|

2.40kg/m2

|

2.04kg/m2

|

|

Rolls per pallet

|

20

|

21

|

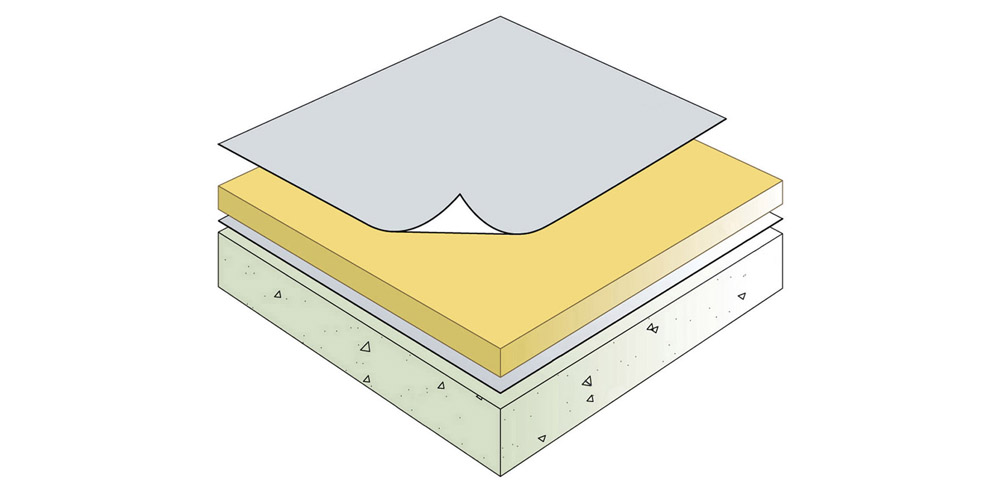

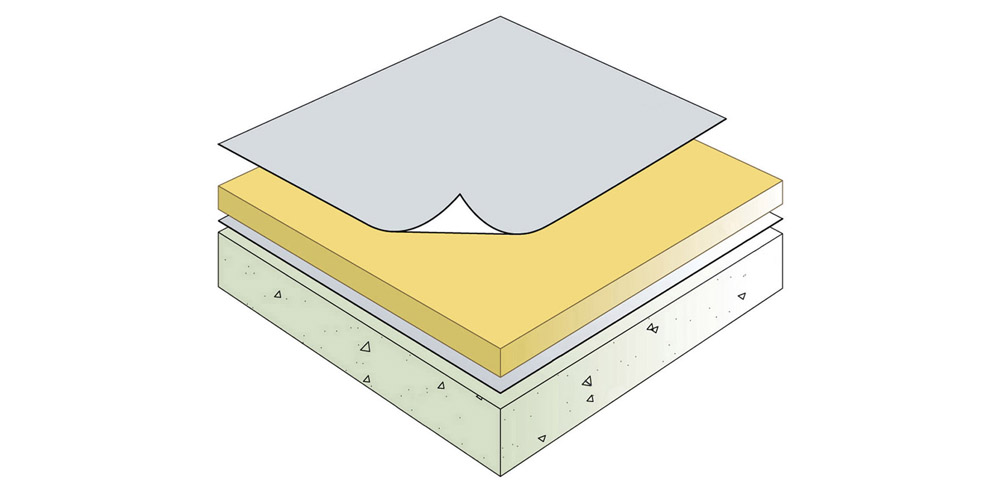

Typical warm roof installation

Ensuring the substrate is clean, dry and free from all dust and laitence, prime the deck using Fatra FF817 Primer.

An appropriate bituminous vapour control layer should be installed on to the cured primer. Fatra have a range of self-adhesive and torch-on VCLs available, please contact us for further details.

Apply Fatra FF867 insulation adhesive to the vapour control layer. The adhesive should be applied in 5mm beads at 300mm centres in the centre of the roof and 150mm centres for the perimeters.

Lay the tissue-faced thermal insulation board in a staggered bond pattern on to the adhesive and apply pressure to the board. Only install the amount of insulation that can be weatherproofed on that day.

After laying the insulation board, roll out the FF807 membrane loose over the board making sure the membrane is running straight and the selvedge is lapped correctly.

Apply Fatra FF859 polyurethane adhesive to the insulation at a rate of no more than 4m² per litre. Wait until the adhesive ‘foams’ and then roll the membrane into the wet adhesive and apply pressure using a roller or a soft brush.

The laps are then hot air welded with a heat gun to create a homogeneous, watertight seal.